News & Case Studies

- Details

- Written by Administrator

Keep up to date with our latest news here: https://kitocrosby.com/news/

- Details

- Written by Administrator

The Crosby Group’s new state-of-the-art facility in Hampshire, UK has been opened by Havant’s mayor, Councillor Rosy Raines.

Cllr Raines cut the ribbon as Crosby, a global leader in lifting, rigging, and material handling hardware, welcomed over 50 channel partners and additional guests from around the world to the 16,500 square-foot site in Waterlooville.

The facility manufactures Crosby’s Straightpoint and BlokCam brands, which are leaders in load monitoring and crane camera technologies respectively. The factory is already fully operational, having completed a successful move from the original location, retaining 100% of existing staff.

Thomas Dietvorst, Sr. Global Product Director, Wire Rope Hardware & Tech Solutions at The Crosby Group, said: “The new facility provides more than just additional square-footage. We can now manufacture significantly more product through layout improvements and subsequent efficiency gains. Beyond that, we are in an even better position to attract staff with a better environment for existing and new employees.”

In addition to Cllr Raines, who cited the importance of manufacturing in the area, Crosby hosts included Robert Desel, CEO of Kito Crosby; Wim Fabricius, Managing Director EMEA; and Travis Buck, Commercial Director EMEA.

All attendees enjoyed an on-site lunch, group tours, and sessions at a Crosby BlokCam demo station and the Rig Safe Rig Smart European Trailer. The event also featured tours of the nearby Portsmouth Dockyard.

Dietvorst added: “Overall, the event was a fantastic success with many commenting on the operational improvements they have seen with the move to the new facility – most notably a reduction in lead times due to the additional capacity and leaner manufacturing flow.

“We are growing fast. Not only have we invested in a new facility, but we will next invest in additional machining capacity.”

- Details

- Written by Administrator

The Crosby Group will relocate to a larger facility for the production of its Crosby Straightpoint and Crosby BlokCam products in Hampshire, UK on February 22, 2023.

The Crosby Group will relocate to a larger facility for the production of its Crosby Straightpoint and Crosby BlokCam products in Hampshire, UK on February 22, 2023.

The Crosby Group’s production facility for its load monitoring equipment and crane camera systems will make a short trip inland to Waterlooville from the current location in Havant on England’s south coast.

With the new facility, the company will double its floor space and this will facilitate improved workflow; the site suits current production requirements but can be extended in line with future demand.

Thomas Dietvorst, Director of Technology Solutions at The Crosby Group, said: “We knew upon acquisition of Crosby Straightpoint and Crosby BlokCam that we would need to eventually invest in a larger facility to facilitate growth plans. The new site meets our requirements and immediately gives us a larger factory, improved capacity, and enhanced stock levels—and will pass reduced lead times onto channel partners and the point of use. Staffing levels have doubled over the past four years, and this move also reflects that.”

He added: “Overall, we will be able to react faster to market and customer demand. We are likely the only load cell manufacturer that has all production processes in-house. Our ambition is to grow further and bring even more technology and innovation to the lifting industry.”

- Address:

123 Proxima Park, Houghton Avenue,

Waterlooville,

Hants,

PO7 3DU - Telephone number:

+44(0)2392 484 491, remains unchanged

- Details

- Written by Administrator

Malaysia-based Goforth Corporation Sdn Bhd, a specialist in fabrication and assembly of heavy rigging and lifting equipment, used four 100t capacity compression load cells from Crosby Straightpoint to weigh a triethylene glycol (TEG) regeneration unit skid at Port Klang.

The 17.5m (57 ft.)-high, 12m (39 ft.)-long, 6m (20 ft.)-wide structure, integral to a process that removes water from natural gas, was four-point weighed to ascertain the final load out weight for installation and to locate the centre of gravity so that the correct lifting sling lengths were made to enable a horizontal lift. A final weight of 96.25t was recorded against an initial target of 100t, atop a self-propelled modular transporter.

The load cells were sourced from Goforth’s stock—the company is a Crosby Straightpoint distributor and keeps an entire fleet of load monitoring equipment calibrated for accurate force measurement across Malaysia. They were used to record real-time data from all four load cells, which was recorded at a safe distance on a laptop with INSIGHT datalogging and centre of gravity software, and Handheld plus, a rugged and versatile digital display with a broad range of features, suitable for all Crosby Straightpoint load cells.

Adrian Ng, executive director at Goforth Corporation, said: “Calculating the load was important because only with the right sling lengths will the hook position directly over the centre of gravity, making sure that the structure is level during all subsequent lifting and installation activities. The method allowed us to constantly maintain a safe distancing during the project, keeping the team out of the required safe distance radius of the structure.”

As Adrian explained, multiple load cells can connect wirelessly to Crosby Straightpoint’s PC software, in addition to a handheld display, which improves safety and efficiency. INSIGHT allows users to weigh and verify the centre of gravity of large and heavy objects that may not be evenly proportioned, utilising a wireless range of 700m (2,300 ft.). Up to four load cells can connect to the Handheld plus and four Bluetooth enabled load cells to the iOS and Android HHP app. INSIGHT software connects to up to 126 load cells.

Using these wireless load cells, maintenance and repair costs are all but eliminated due to the absence of cables and connectors. They are machined from high-grade 17-4PH stainless steel, providing excellent strength and corrosion resistance, making them suitable for the most arduous industrial conditions. At the heart of the ergonomically-designed Handheld plus, meanwhile, is a powerful printed circuit board (PCB), providing selectable units of measurement (tonnes, lbs., kg and kN), programmable audible overload alarm, peak hold, pre-set tare, and a resettable overload counter.

Adrian said: “Business is fluctuating and demanding, with short lead times. It is imperative that during the down turns we train and up-skill, so we are ready to take on the jobs at short notice; we are generally engaged towards the end of the supply chain before loading out.”

He added: “We deal with all sectors of the economy that require lifting, rigging, weighing, testing, and inspection services. We provide load cells for high-rise construction, infrastructure, shipbuilding, and turnkey projects, such as mass rapid transit systems and process skids. Additionally, our after-sales services include refurbishment work, change out of wire ropes, inspection and certification of mooring systems, and load tests that can cater for 1,000t of weight. We also have a non-destructive testing team.”

- Details

- Written by Administrator

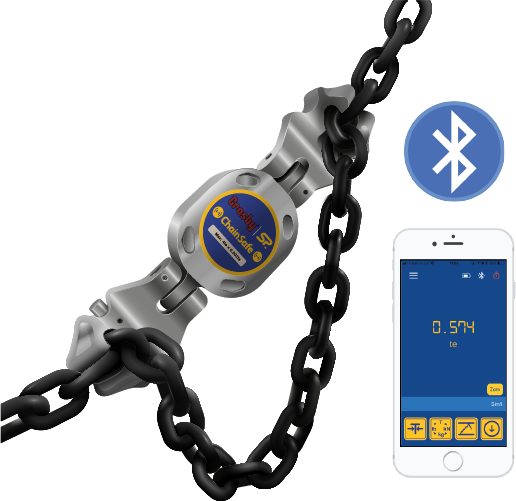

The Crosby Group announces the launch of the Crosby Straightpoint ChainSafe – for the protection of cargo during transport.

The ChainSafe, with a 4t capacity, is a smart dynamic solution for measuring the load on lashing, load securement, tie-downs and chain sling legs, and is designed in particular for the transportation and construction industries to secure loads and cargo. Connected to Crosby Straightpoint’s free Android or iOS HHP App, which has real-time overload alerts and reporting for later analysis, and with a range of 100m (328ft), the ChainSafe ensures the safety of cargo during transit.

The ChainSafe improves safety and efficiency by measuring the tension on your chains avoiding costly breakages and maintenance and protecting your cargo. It is the perfect combination with a Speedbinder or Lebus Loadbinder to accurately monitor the tension on tie-downs.

Because ChainSafe is equipped with a comprehensive range of optional chain fittings offered by The Crosby Group—such as hooks, lashing and chain shorteners from Gunnebo Industries and Crosby, the device is totally adaptable. The design has an unrivalled strength to weight ratio, with a completely sealed stainless steel enclosure providing IP67 or NEMA6 environmental protection, making this industry-leading dynamometer even more suitable for use in the harshest environments.

The Crosby Straightpoint ChainSafe is the latest release in The Crosby Group’s growing platform of technology-centric products and solutions.

Thomas Dietvorst, Director of the Technology Solutions division, said: “We are uniquely positioned to deliver productivity and safety advantages to the point of use, given the lifting and lashing applications that already utilize Crosby and Gunnebo Industries-branded products, in addition to other products and technologies in the portfolio. Transportation professionals, and those responsible for small to medium crane lifts, have already noted the benefits of adding ChainSafe to their lifting and lashing applications and how precious cargo is protected.”

Additional features include an unrivalled battery life of five years, based on four hours of use per day; and an internal antenna.