News & Case Studies

- Details

- Written by Tanya

Straightpoint’s Gavin Arnell Excels in First LEEA Examination

Straightpoint’s Gavin Arnell Excels in First LEEA ExaminationStraightpoint product technician Gavin Arnell out-performed lifting equipment professionals of far greater experience to pass the Lifting Equipment Engineers Association (LEEA) P1E Foundation Course recently.

The Foundation Course is the basic level training course offered by LEEA, which is based in Huntingdon, UK but established across the globe as the leading representative body for all those involved in the lifting industry worldwide. It offers a number of courses ranging in duration and tailored for varied levels of expertise and types of equipment.

Arnell participated in a three-day programme that took place at LEEA’s Osprey Court training facility near the association’s headquarters in Ramsay Court, which is also on the Hinchingbrooke Business Park. P1E includes 28 modules covering a range of subjects including, standards and codes of practice; wire rope and wire rope slings; overhead travelling cranes; and mobile cranes.

He said: “Having never seen or heard of much of the subject matter covered by the modules, I was apprehensive about tackling the content in an exam situation. However, as the course progressed I became more confident and embraced it as a learning experience. I was still pleasantly surprised though when LEEA confirmed I had passed.”

The foundation level exam is a prerequisite for studying at advanced level and Arnell has already booked to take the Lifting Equipment General (LEG) Advanced Programme, a five-day intensive course, in April. The LEG course offers hands-on practical training to complement essential theory sessions. Content is based on lifting accessories and includes thorough examination procedures and criteria for continued periods of service.

Arnell said: “I am looking forward to the challenges of the LEG course and am sure I can apply lessons learnt in P1E to help me at the more advanced level. I know there will be lots of references to below-the-hook and rigging equipment that will reinforce my understanding about the sector of the industry in which Straightpoint operates.”

Alfie Lee, operations director at Straightpoint, said: “Gavin was the only person on the course with no previous experience and he passed first time. Some of the other candidates were on their second attempt and were perhaps not as successful even this time around. He can take a tremendous amount of encouragement and confidence from that moving forward.”

Both the P1E and LEG courses contain modules on wire rope and wire rope slings, which Lee said aligns the content with Straightpoint strategy. He explained: “We are just starting to explore the wire rope industry in greater depth. Having someone with this qualification will be invaluable and will help us understand how our customers use our products and the problems they face on a day-to-day basis within the lifting industry.”

- Details

- Written by Tanya

Radiolink plus Chosen for Air Transportation to Remote, Demanding Jobsites

The strength to weight ratio of force measurement, load monitoring and suspended weighing load cell equipment is particularly important when there is a requirement to transport products by air, as a Western Australia-based end user explained.

Allplant Inspections uses load cells to complete annual and other inspections on mobile cranes, often located at mines across the sprawling Golden State that covers almost a million square miles. Covering such distance would be impossible without air travel, where weight has to be kept to a minimum.Allplant has five load cells in its inventory, including a 25t and two 12t Radiolink plus units from Straightpoint, which can be employed close to the coastal, Silver Sands company headquarters or over 2,000 miles away in a remote mining town, which are commonplace in the state’s northern region. Allplant is also a regular visitor to numerous construction sites in the geography.

Mitchell White, classified plant inspector, said: “The Straightpoint load cells’ light weight, accuracy and ability to remain in calibration are standout features. The low weight is hugely advantageous given how frequently they have to be transported by plane. We have five load cells in total but the non-Straightpoint products rarely see the light of day.”

David Ayling, director at Straightpoint, said: “Mitchell is among an ever-growing number of lifting and rigging professionals who have highlighted our products’ suitability for air transportation. Fittingly, the Radiolink plus is manufactured from high-quality aircraft grade aluminium. The oil and gas industry has pioneered its use, given the requirement of the sector to travel to rigs and other offshore locations by helicopter, where every gram counts.”

Once offshore, on a mining site, or in another demanding industrial environment, safety and performance are paramount. The Radiolink plus’s advanced internal design structure allows the use of a separate internal sealed enclosure providing the load cell's electronic components with IP67 environmental protection even with the battery cover plate missing, making it suitable for use in the harshest environments.

Allplant uses the Radiolink plus load cells, including its newest 12t wireless version, on a variety of mobile cranes ranging in capacity up to 1,250t. It also inspects pressure vessels, elevated platforms, hoists, concrete boom pumps, telehandlers and other plant equipment.

White said: “We use the load cells for different work, including full boom capacity tests to 100% WLL [working load limit] of the crane and also line pull tests to 100% WLL winch capacity. Such load tests need to be accurate and most sites do not have known test weights so a load cell is critical. The newest 12t load cell is the only wireless one we have and it has already proved its worth in a number of applications.”

Allplant has employed the 12t load cell and Wireless Handheld plus to test the load indicators on two mobile cranes recently. It was called to a large gas plant construction site to complete inspection of a Tadano GR-800 rough-terrain crane, which was one of over 250 cranes in the user’s fleet. Meanwhile, local rental firm Pinjarra Crane & Access Hire required similar tests on a Liebherr LTM1100 mobile at its depot in Pinjarra.

The Radiolink plus comes as standard with a flight carry storage case up to 35t (77,000 lbs.) and a shipping crate for larger capacities.

- Details

- Written by Tanya

Slack Liners Employ Load Cells to Measure Line Tension

Thrill seekers who participate in an extreme sport called slack line, have employed Straightpoint wireless load shackles and other load cells to measure the tension on lines before stepping onto them, sometimes hundreds of feet in the air.In its simplest sense, slack line is different to tight rope walking in that the line has slack in it. When in use there is an appreciable dip in the line between the anchor points where the person is walking. Slack liners use force measurement equipment to record a standing tension when the line is tightened and measure leash falls.

David Kingston, a physical therapist by day, has been slack lining for 16 years and is a long-time user of dynamometers. However, he has only recently embraced wireless load shackles which, ironically, are more typically suited to low headroom applications in the industrial sector.

Kingston said: “We walk on 1-in.-wide flat webbing made of different materials, usually nylon or polyester. Tight rope walkers tend to have their lines much tighter and also have guy wires that keep the line from swinging at certain intervals across the line. With slack lines there tends to be more movement. When we take the slack line up, we call it high lining.”

The highest line Kingston has walked was at Taft Point, in Yosemite, California, where he crossed 170 ft. at a height of 3,200 ft. The longest high line he has walked is 250 ft., but he has walked many lines ranging from 40 ft. to 330 ft and his longest low line crossing without a harness is 666 ft.

Lines are anchored across canyons and rocks on bolts or natural features. Kingston explained that if four glue-in eye bolts are on one side of a canyon, he builds an anchor to equalize them and share the load. Each bolt is also backed up to the master point individually so if one bolt breaks the master point would not extend or change position. Slack liners walk on a single piece of webbing that is taped to a backup line. Kingston uses two forged titanium 22,000-lb. rings that follow as he walks and attach him to a harness with a leash.

He said: “Walking the lines is the safest part of the day because once it is set up you are actually tied in. Sometimes during the set up, scrambling to the tops of the rocks, that isn’t always the case. Some of the hikes and climbs to the tops are definitely more dangerous than the sport itself.”

Slack liners are increasingly utilizing Straightpoint force measurement technology with its Wireless Handheld plus units. Kingston said: “The wireless option is beneficial since I normally tighten my lines on the opposite side of the gap to where the load cell or load shackle is rigged. We usually walk lines with anywhere from 500 lbs. to 1,000 lbs. standing tension. Using Straightpoint equipment I can create a graph and actually see data related to peak loads.”

He added: “I really enjoy the rigging process. I am known for my safe and strong rigging techniques in the slack line community. It’s great to have a dynamometer in the system that adds length to an anchor so we don’t have to jump when we walk off the line. The ends of the lines are the most dangerous because if you fall you have to catch the line, as ending up on your leash can swing you into the rocks.”

Kingston concluded: “I enjoy walking on the slack lines and high lines because of the mindset that one has to adopt. You have to be completely focused on the task at hand. All your thoughts about daily life disappear and at the same time you become hyper aware of your surroundings and body. You can feel yourself moving at light speed and be motionless at the same time when you need to be.”

- Details

- Written by Tanya

New Products Detailed in Latest Straightpoint Catalogue

Straightpoint’s global distributor network has received the manufacturer’s latest catalogue that details new products, including the Wireless Low Headroom Link and Wireless Impact Block. They are among a myriad of other force measurement, load monitoring and suspended weighing load cell innovations in a 48-page document that was launched in three languages on 12 October 2016. Now available in a wireless version, the Straightpoint range of low headroom links is designed to provide accurate measurement of loads in the most challenging applications where headroom restrictions are a major factor. The Impact Block, meanwhile, measures the shock load and weight of branches as they are cut during tree felling or maintenance; it has proved popular with tree surgeons and other professionals from the arboriculture industry. Among other changes to the catalogue are details of ATEX and IECEx hazardous area approval on much of the wireless load cell range. At the turn of the year, Straightpoint launched a version of its most popular product, the Radiolink plus wireless load cell, which met Zone 0, 1 and 2 hazardous area classification, but the catalogue includes the Wireless Load Shackle, Wireless Compression Load Cell and Running Line Dynamometer ranges in ATEX and IECEx versions, in addition to what David Ayling, director at Straightpoint, called a “game changing” product in the Wireless Load Pin for hazardous areas. Ayling said: “The catalogue itself, like every edition before it, represents completion of a large-scale project in its own right, combining the expertise of many different departments at the company and our trusted sources in industry. However, what gives the team the most satisfaction is that the document encapsulates innovative, technologically advanced load cells and other equipment, the application of which makes the lifting industry a safer place.” The distributor network is abuzz over a revelation on page 22 of the catalogue that Straightpoint will unveil Stage Safe, a load cell for the entertainment industry, in the coming months. Its systems have already been widely embraced by theatres and live events venues, but end users will soon have access to a dedicated product. Ayling said: “We staged last year’s launch of the Wireless Load Shackle at an entertainment industry event, while the Loadlink plus and other products have also been widely consumed by the sector. However, it is an industry that requires dedicated solutions because of the many unique requirements of lifting in such environments and the breadth of potential that’s apparent. Stage Safe is much anticipated and we look forward to full details being a cornerstone of the next edition of the catalogue.”Download or request your hard copy here

- Details

- Written by Tanya

|

|

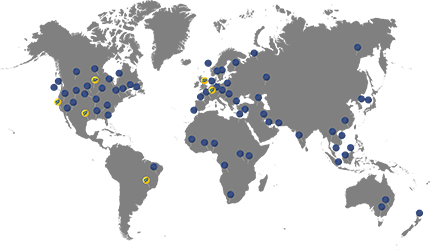

|

| Scale People Inc. | RD Jacobs | Cooper Instruments |

The Scale People Inc., of Newport News, Virginia; R.D. Jacobs Company, of Fort Lauderdale, Florida; and Cooper Instruments & Systems, of Warrenton, Virginia—in that order—have all joined in recent months. Each has an established presence in the industrial scale marketplace, widening Straightpoint’s scope beyond its traditional lifting and rigging sectors.

Rex Cooper, president, Cooper Instruments, said: “We have sold similar products for years, but we have never had the wide range of products Straightpoint offers for the heavy lifting industry. Additionally, we are finding more customers are looking for wireless solutions and they offer a wide range of wireless sensors that align well with our current offerings.”

Cooper’s sentiments were echoed to a large extent by Jim Bloodgood, president, R.D. Jacobs. He said: “I have been aware of the Straightpoint product range for some time. I am a long time distributor of another similar product, but Straightpoint offers a number of excellent solutions that are not available through other suppliers.” Bloodgood also alluded to the “exemplary” support he has received from the load cell manufacturer since joining its network.

The Scale People agreement also captures the essence of an outreach campaign that is being spearheaded by Wayne Wille, who recently joined Straightpoint as technical sales manager, with the company serving process control, laboratory, medical and commercial industries. Cooper and Bloodgood both expect demand from the aerospace sector, while automotive, food processing, utilities, shipping and energy were among other industries referenced by Straightpoint’s three new partners.

Wille said: “These appoints serve as landmarks as I continue to enjoy the challenges presented by my new role. It will be interesting to monitor as they introduce our product range to their customers and we develop an understanding of what might be required from each party to explore the mutual opportunities presented by the respective partnerships.”

He added: “It is within my breadth of work to introduce Straightpoint’s products to markets beyond cranes and rigging, which is hugely rewarding given the extent of our technological innovation and the scale network’s familiarity with state-of-the-art systems and software that offers them a complete solution.”

John Molidor, general manager, Straightpoint Inc., said: “While we are a below-the-hook equipment manufacturer, we offer a technologically advanced rigging product. What Wayne brings to the company is a background and connections in the U.S. scale dealer network, which is more mature in terms of its uptake of such technology. That is naturally very exciting.”