News & Case Studies

- Details

- Written by Tanya

Gator Test Rig Utilizes Straightpoint Load Cells

Straightpoint force measurement, load monitoring and suspended weighing load cell equipment is integral to fabrication and periodic testing of equipment at two Southern Louisiana facilities that serve the U.S. marine, oil and gas industries.Gator Rigging, Inspection, Testing & Supply LLC offers a myriad of rigging services, including inspection, load testing and critical lift consulting for Industry leaders across the state.

The company utilizes Straightpoint load cells at its Morgan City and Cut Off, Louisiana sites. Both locations employ horizontal test beds with the Morgan City branch also having vertical testing capabilities to 100 tons. Plans are in the works to add vertical test capabilities at the Cut Off location in the months to come.

In one recent application at the Morgan City site, Gator used load cells in conjunction with its vertical test bed to complete an annual inspection of marine equipment. A Straightpoint load cell was rigged in the vertical test bed using two 25-ton shackles. With a four-leg sling, the equipment was then lifted and weighed with both load cells providing almost precisely the same result.

Jeremy Houghton, marine consultant and inside sales at Gator Rigging, said: “The inspection was a success and we contemplate utilizing Straightpoint equipment again for similar applications in the future.”

John Molidor, general manager at Straightpoint Inc., said: “We were contacted by Gator Rigging about this time last year. It was a pleasure to help them improve their ability to provide top quality services to high profile marine, oil and gas customers in the region.”

Straightpoint load shackles are manufactured from Crosby’s industry-leading 2130 Carbon and 2140 Alloy Bolt Type Anchor Shackles to 120 tons and the GN H10 Alloy Bolt Type Anchor Shackle or equivalent in greater capacities. The wireless data logging software allows for simultaneous control, display and real time data logging of up to 100 Straightpoint telemetry load cells. Load shackles are also available in a cabled version, particularly suited to subsea environments.

Gator Rigging’s marine industry customers require use of the test rigs for a variety of reasons, including the certification of weights required to complete lift plans and load outs of equipment. Houghton, who is responsible for consultancy and inspection at the Cut Off facility, added: “As a marine consultant, when assisting customers with the fabrication stage of jobs, the equipment must have a certified weight so the engineers can complete the lift plans and drawings for upcoming load outs of equipment. The load cells provide accurate weights so our engineers can produce these lift plans and drawings.”

Plans are already in place to build a fourth custom-built rig at Cut Off, expected to pull 100 tons or even more.

- Details

- Written by Tanya

Straightpoint launch ATEX Load Cell

Straightpoint launch ATEX Load Cell

Straightpoint will launch an ATEX and IECEx version of its most popular product—the Radiolink Plus wireless load cell—next month (November).

The explosion proof product will be assembled on a brand new production line ensuring that the force measurement, load monitoring and suspended weighing load cell manufacturer can continue to provide quick delivery to job sites around the world.

Meeting Zone 0 classification (an area in which an explosive gas atmosphere is present continuously or for long periods) is unprecedented in below-the-hook force measurement technology with other suppliers providing products for use in areas categorised only as hazardous as Zone 2 (an area in which an explosive gas atmosphere is not likely to occur in normal operation and, if it occurs, will only exist for a short time).

Roshan Divakaran, design engineer at Straightpoint, who has overseen the product’s development, said: “We don’t believe there is another wireless load cell on the market that is Zone 0 certified, which makes this a tremendously significant product launch for the sectors that require such technologies. The requirements of the oil and gas industry were a primary focus throughout the design and certification process.”

The criteria of ATEX and IECEx are broadly similar, although the former is widely accepted throughout Europe, while the latter is required in many other global markets.

The ATEX version of the load cell and wireless handheld unit contains several safety components that permit its use in Zone 0 environments. A separate storage area has been created at Straightpoint’s Havant, UK headquarters and all production personnel have been specially trained in the assembly of the explosion proof units.

Straightpoint director David Ayling said: “We made a decision in early 2014 to introduce the benefits of our best selling product—the Radiolink Plus—to industries and applications where products that meet the requirements of ATEX are required to work in extremely hazardous environments. I am delighted for Roshan and the team that we have executed our ambitious plan to launch the product by the end of 2015. It has been one of the biggest development projects in the history of the company and the interest we’ve already received suggests that our new production line will be kept extremely busy.”

Divakaran, working in close collaboration with the Sira Certification Service, an independent certification body, has been working on the ATEX and IECEx project since he joined the company last year.

He said: “Developing a Zone 0 product has been very challenging given the extent of the standards and safety regulations that we have had to meet as we produced documents, prototypes and the final product. Our goal was to meet this criteria whilst making minimal changes to an already excellent, well-renowned product; we feel we have been successful in achieving that.”

Ayling concluded: “A significant amount of our business comes from the oil and gas sector. The explosion proof certification will vastly increase the scope of application we can serve and provides our distributors with unique selling points both in terms of the classification level and our ability to deliver the product within a few days.”

- Details

- Written by Tanya

Straightpoint Load Cells Weigh Gas Facility Components at US Port

Straightpoint load cells were integral to the safe offload of a 718-ton absorption tower and a flash vessel from SAL Heavy Lift’s Type 116 MV Amoenitas vessel at the Port of New Orleans, Louisiana.

The absorption unit is an industrial-size tower (it measures 170 feet long; 24 feet wide; and 23 feet, 7 inches high) used to separate out components of rising gas, while the flash vessel, although smaller, will be the main component of the flash recovery system at the major installation project.

The Amoenitas arrived at the port’s Louisiana Avenue Terminal in mid-January after a 45-day trip from Shanghai, China. It boasts a top speed of 17 knots (nearly 20 mph); the ability to carry cargoes weighing upwards of 900 tons; and two cranes, each offering a capacity of 450 tons and two auxiliary hoists of 35 ton capacity apiece.

SAL specializes in the sea transportation of heavy lift and project cargo. Its offshore subsidiary focuses on developing and delivering installation solutions for the oil and gas and renewable energy sectors.

Straightpoint worked alongside Marine & Industrial Supply, the rigging and testing solutions business responsible for providing the load cells and shackles; and Fracht FWO Inc., of Houston, a North American subsidiary of the Swiss freight forwarding company that oversaw the offload to barges positioned alongside deck cargo pontoons.

Straightpoint worked alongside Marine & Industrial Supply, the rigging and testing solutions business responsible for providing the load cells and shackles; and Fracht FWO Inc., of Houston, a North American subsidiary of the Swiss freight forwarding company that oversaw the offload to barges positioned alongside deck cargo pontoons.Charles Duprey, projects manager at Fracht FWO, explained that the load cells played a key role in the transfer of the valuable units from sea to barges before continuing their journey on land as there was a discrepancy over the weights of the loads that were recorded in the transportation documents.

John Molidor, the general manager of Straightpoint’s US operation, said: “Within 10 minutes of my phone conversation with Charles Duprey from Fracht I had drafted an email detailing my conversation with Charles which included his contact information to Ricky Thompson, general manager at Marine & Industrial Supply. It was late in the day West Coast time but from what I understand Ricky was in touch with Charles first thing the next morning.”

Duprey said: “The load cells were crucial given that when we loaded the absorption tower and flash vessel in China the lift weight in the barge was drastically inaccurate so for safety reasons we wanted to weigh them again in New Orleans. Importantly, when we used the load cells to weigh the items at the port, the weight matched the documents of the manufacturer which told us that the measurements recorded by the barge crane instruments were incorrect.”

Duprey and his team at Fracht FWO have been executing such offloads for the mammoth project for over 18 months and vessels have been arriving in New Orleans with equipment loaded from ports all over the world, adding to the complexity of the freight forwarding operation. Lifting and rigging technologies have been inherent to the safe progression of the project.

Straightpoint’s force measurement, load monitoring and suspended weighing products are at the pinnacle of technological advancement, offering users the ability to monitor the pick points of dynamic loads while they are being moved and relay the information 100% wirelessly to a PC.

Duprey said: “This wireless capability was hugely beneficial to the project, as was the convenience of being able to change the capacity in which the information was displayed from tons to pounds, for example. The Marine & Industrial Supply team were fantastic as was the capability and performance of the Straightpoint load cells.”

Thompson said: “The entire group was very professional and a pleasure to work with. Straightpoint load cells are well known to be the very highest quality, and our team at MIS works hard to provide impeccable service to our customers.”

Molidor concluded: “It is Straightpoint’s ever increasing involvement in these high profile engineering projects that is allowing us to transform the lifting industry in an accelerated fashion. The use of the Straightpoint product line by giants like Bechtel, Chicago Bridge & Iron Company, and Kiewit just to name a few is invaluable as these world leaders are known for setting industry trends.”

- Details

- Written by Tanya

Straightpoint Wins Business of the Year Award

Straightpoint was named Business of the Year 2014 by a leading business coaching company who selected the local cell manufacturer based on profit growth, sales growth, marketing excellence, team leadership and development.

Straightpoint was named Business of the Year 2014 by a leading business coaching company who selected the local cell manufacturer based on profit growth, sales growth, marketing excellence, team leadership and development.Action Coach works with firms in 50 countries but the Business of the Year award was presented to one winner from its portfolio of companies in the UK’s south central region, which covers Portsmouth, the Isle or Wight and Southampton.

Gary Mullins, of Action Coach, who works with Straightpoint’s team at Havant-based headquarters, said: “We measure companies based on actual profit and loss figures, financial and percentage growth as well as steps taken by the business to build strong systems and most importantly a high performance team.”

Mullins has worked with Straightpoint for over a year, initially with director David Ayling and then more extensively with senior management and other key team members. He revealed that the load monitoring and suspended weighing load cell specialist emerged top in every judging category.

He said: “I have seen David develop personally and show great leadership skills. His abilities to build the key elements of a strategic plan, develop and implement action plans, and focus on building his team have stood out in particular. He has built a tremendous platform from which to take the company to the next level.”

Ayling said: “We are thrilled to win the award and hugely appreciative of the guidance and encouragement Gary has given the team and I to achieve our business goals. I have a great sense of satisfaction in that we can attribute part of our success in the categories in which we were judged to the partnership we have developed with Action Coach.”

He added: “The business continues to enjoy aggressive growth and I am glad that Gary is available to provide support and a perspective from outside the company. While I dedicate the accolade to each and every member of staff that made it possible, Gary himself deserves a great deal of credit.”

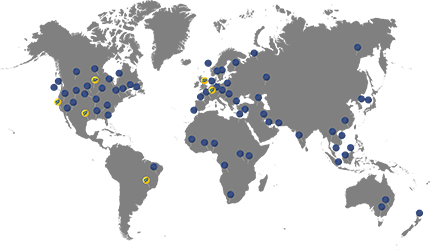

Mullins highlighted Ayling’s commercial skills and development of the company’s distribution network. He anticipates that, in just five years, Straightpoint will have an even stronger global presence with a robust US-based business and a distributor network that will be the envy of competitors.

He added: “The effort David has put in has been immense and he has achieved results that he is rightly proud of. To build a great business you need a great team and David is building this both internally and throughout his global network of partners.”

Due to extensive global travel, Ayling was unable to accept the award in person and operations manager Alfie Lee represented Straightpoint at the recent Action Coach awards evening. He said: “I was very proud to accept the award. I have known David and his business partner Peter McGreal for in excess of 25 years and have watched with interest as the business they purchased back in 2002 has grown and flourished under their leadership. To now be part of that growth and to be recognised for it by Action Coach is very rewarding.”

Lee joined the company in May 2014 and has attended Mullins’ training events in addition to one-to-one sessions. He added: “Gary is now mentoring us on trying to help us adapt the business to focus on streamlining stock levels. As the newest member of the board of directors it was an honour to accept this prestigious award.”

- Details

- Written by Tanya

Already Trending on Facebook

Already Trending on Facebook

Mr Loadlink Blog has been relaunched

Start as you mean to go on …

Welcome to the first Mr Loadlink blog of 2015! Unlike a lot of companies where communication with customers, partners and industry fades away as they become distracted by the day-to-day demands of the business, Straightpoint remains committed to keeping you informed, educated and entertained through content, tailored for our variety of audiences across the world.

Content and marketing messages are key components of our growth strategy and the busier we get (and we’re busy!) and the faster we grow, the more communicative we will become..... To read more please visit Mr Loadlink