News & Case Studies

- Details

- Written by Tanya

Straightpoint Inc.’s force measurement, load monitoring and suspended weighing load cell equipment is available through a General Services Administration (GSA) Schedule Contract held by Newport News, Virginia-based The Scale People Inc. with immediate effect.

GSA Schedule Contracts, also known as GSA Schedules or Federal Supply Schedules, are indefinite delivery, indefinite quantity (IDIQ), long-term contracts under the General Services Administration's Multiple Award Schedule (MAS) Program.

A myriad of entities are authorized to purchase from the schedules, including wholly-owned government corporations; universities; Army Corp of Engineers; Federal Maritime Commission; U.S. Navy; and Department of Transportation. Additionally, a number of international organizations are permitted to source through the contracts, including the European Space Research Organization; Intergovernmental Maritime Consultative Organization; and United Nations.

Straightpoint equipment is available through The Scale People’s Schedule 66; GS-07F-021BA. Schedule 66 covers scientific equipment and services, providing one stop shopping for all general purpose and specialized laboratory equipment and furniture; unmanned aerial vehicles; measurement and testing equipment; and laboratory test and analysis services.

Chris Buck, president at veteran-owned The Scale People, said: “Straightpoint will be a great addition to our five-year GSA contract. The Straightpoint line will help satisfy the government's need to monitor overhead lifting for safety purposes and other related applications. We have enjoyed being a Straightpoint distributor and this only adds further value as we continue to explore avenues of mutual opportunity.”

The Scale People has serviced, calibrated and sold state-of-the-art equipment in weighing and measuring technology for nearly 60 years. Buck and the team are dedicated to providing custom solutions that best fit requirements by supplying service and expertise in installation and maintenance of any weighing system. All services are ISO/IEC 17025 and GLP/GMP accredited.

Jeff Miller, general manager at Straightpoint Inc., said: “The Scale People has been part of our U.S. dealer network since last fall as we looked to actively raise our profile in the scale marketplace. Endeavors to that end have been ongoing and we’re delighted to complement that activity through the GSA Schedule Contract program. This further strengthens our partnership and we look forward to offering our full support as they engage the illustrious customer base that sources equipment through Federal Supply Schedules.”

Organizations eligible to source through the GSA system can contact Straightpoint Inc. 805-246-1462 or The Scale People Inc. directly Call: 1-800-964-1535

- Details

- Written by Tanya

Anchor Industries used water bags in addition to a variety of force measurement and rigging equipment to complete load tests on a Liebherr crane aboard a vessel in Cape Town Harbour, South Africa recently.

Anchor accepted a scope of work from Dormac Marine & Engineering to complete an overload test of the crane, constituting a 550t load being applied to the main hoist. Additionally, Anchor was required to complete a 55t load test of the auxiliary hoist as well as a 50t calibration test of the main hoist after the 550t overload test was complete.

Four 75t capacity Radiolink plus wireless load cells and four 30t capacity wireless low headroom links, all manufactured by Straightpoint and sourced from Anchor stock, provided data to handheld devices throughout the project. Another four 120t load cells from a different manufacturer completed the force measurement fleet for the job.

Tyrone Tilley, national services manager at Anchor, said: “With a test this large there is always a certain level of stress and to have the Straightpoint products involved gave the team added assurances that the equipment was going to deliver in a pressurised environment. The 120t load cells were from old stock; we are in the process of phasing out those units and replacing them with Straightpoint equipment.”

For the main overload test, a dozen water bags were used in a near-40m, three-tier cascading rig. At the top and middle were two 100t and two 40t bags, while three 20t and a 30t bag combined at the bottom. Supporting rigging equipment was allocated to each lifting point; for example, Point 2 for two 40t bags in Tier 1 included a 100t x 7m roundsling, two 55t safety bow shackles (above and below the 75t load cell), followed by the water bag.

Tilley said: “The additional capacity in the water bags was to account for water displacement owing to the fact that they were pushing against each other. Of the 650t capacity we had I estimate that we lost approximately 50t to 70t.”

The Radiolink plus is Straightpoint’s most popular product. The range of low headroom links, meanwhile, is designed to provide accurate measurement of loads in the most challenging applications where headroom restrictions are a major factor. In this case, Anchor wanted to limit the height of rigging in-between water bags. Constructed from high strength alloy steel and exposed to an array of testing during development, the tension load cells are designed to work with industry standard shackles. Further, said Tilley, they are lightweight and user-friendly.

Anchor was aboard the vessel over a three-day period. Tilley explained that the first day was used for transportation of the equipment in two flat-bed truck loads, then rigging up the water bags. Day two saw completion of the 550t load test, while the two additional tests, rigging down and offloading took place on the final day.

Tilley concluded: “The job was well planned and executed within the timeframe without any significant challenges other than the short lead time; we received confirmation of the job on the 17th of the month and delivered from the 20th to 23rd. We used handheld devices for this project but have recently acquired Straighpoint’s multi-load cell reading software [SW-MWLC] and look forward to applying it on future applications of this nature.”

The Liebherr boasts the Litronic crane management system, a one-level interface between crane and driver. Various analysis tools provide relevant information on the operation and the system empowers the driver to efficiently control the crane and optimise turnover. Stingray, meanwhile, has a design draft of 5m and dimensions of 120m by 40m.

- Details

- Written by Tanya

Rapid Response Solutions (RRS) once again demonstrated the reliability and durability of Straightpoint’s range of force measurement, load monitoring and suspended load cell equipment whilst weighing components of its new 200t capacity Mega Lift.

RRS recently took delivery of its second Mega Lift—it already had a smaller 60t capacity system—and had a requirement to weigh all four rams, two beams and the trackway. The systems lift by extraction of the legs, different to conventional gantries that use a lifting device such as a winch or a strand jack. The complete gantry system and load can be slid on tracks.

Stuart Trinder, sales and distribution manager at RRS, said: “It was important to calculate and document the weight of each item so we known how much load to put on the vehicles when delivering to site. The information is also included in the product’s method statement as some areas where customers wish to set up the equipment have a maximum load limit. The heaviest items were the 2.5t rams so one can imagine the importance of understanding the weight of each component.”

The application showcased RRS’s ability to utilise its existing inventory, including the 5t capacity Radiolink plus wireless load cells that are in each of the company’s rigging vehicles; the 34t capacity truck-mounted Fassi F365A crane; and other below-the-hook equipment.

David Ayling, director at Straightpoint, said: “Rapid’s application resonated with me because it showcased the reliability and longevity of equipment that has been in the field for many years. We frequently communicate to industry about our new and innovative products but perhaps we could more readily champion the volume of kit that has been in service for many years even in the most demanding of industries.”

Trinder said: “The load cells were integral to the operation. We have 10 rigger vans of varying sizes and most carry on board a Radiolink plus. Using equipment at the Portsmouth depot we were able to weigh all the required components within a few hours using our own crane operator, a lift supervisor and a rigger.”

He continued: “Straightpoint’s kit is bullet proof. Their load cells are the best available in the market and they never let the rigging teams down. They often encounter a requirement to check weights in the field as the information provided or stamped on the equipment can prove to be inaccurate.”

Trinder added that the load cells and Mega Lift will again combine onsite whenever there is a need to calculate the accurate weight of a load. “I would estimate that one in three Mega Lift projects require the use of Straightpoint’s equipment,” he said.

For weighing the Mega Lift’s components, the team also utilised RRS’s new Kinetic Enterprise system from Motion Software to document the information, sourced to control inspection compliance processes. In the field, RRS can use the software to manage multiple inspections and issue reports in addition to tailoring LEEA and LOLER-compliant documents and forms. The software is built to create compliant certificates for cranes, forklifts and other equipment.

“The new Mega Lift will give us extra lifting capacity in areas where headroom is limited,” said Trinder. “We anticipate constant utilisation of both units on our own projects or out on hire. Maritime, ship-building and power plant professionals are among those who have noted our expanded fleet and are already making enquiries. It was important to quickly document the weight of the new Mega Lift’s components upon arrival at our depot so we are ready to advance these enquiries.”

- Details

- Written by Tanya

New Clamp On Line Tensionmeter with Bluetooth App

Straightpoint has launched a new product for measuring tension on static lines—the Clamp On Line Tensionmeter (or COLT)—with a state-of-the-art Bluetooth load monitoring app among a myriad of standout features.

Straightpoint has launched a new product for measuring tension on static lines—the Clamp On Line Tensionmeter (or COLT)—with a state-of-the-art Bluetooth load monitoring app among a myriad of standout features.The COLT measures tension on wire rope up to 11,000 lbf (lb. force) / 5,000 kgf (kg force) and up to 1 in. / 25mm diameter. It clamps onto pre-tensioned wire ropes, eliminating the need for additional sheaves or tooling, as is the case with alternative solutions. An integral Bluetooth module, meanwhile, transmits tension data wirelessly to any smart device running the Android or iOS app that also contains an infinite wire rope library. Tension in wire ropes can be measured and logged within a few seconds.

David Ayling, director at Straightpoint, said: “Therein lies the two revolutionary features of the product. Measuring tension of differing wire rope diameters often requires different sheaves to be exchanged, requiring tools and other ancillary equipment. The COLT boasts an integral quick adjustment mechanism, meaning it can be used to measure wire rope diameters from 3/16 in. to 1 in. or 5mm to 25mm.”

He added: “We’ll launch the app with a library of around 20 differing rope types but as our library here increases over time, the information will be forwarded to all app users via updates. They will be available even to users who download the technology upon its launch.”

Wire ropes are complex; composition, size, construction, type of core and lay all need to be considered. A 1 x 7 rope behaves differently to a 7 x 19 or 6 x 36 rope; even wire ropes of the same diameter will calibrate differently because of varying rigidity. End users will leverage the hardware and software benefits of the COLT to simplify tension measuring applications beyond what was previously thought possible.

Ayling added: “As is the backstory to many Straightpoint innovations, we based the COLT on feedback from the end user marketplaces that apply our technologies. Combining industry intelligence with our own research and engineering expertise, we devised a product that fills a gap in the market and supersedes alternative solutions. Further, it raises the bar in tension measuring technology to the stratosphere.”

The COLT features a computer numerical control (CNC) machined aluminium construction with high precision roller bearing pivot; high leverage tensioning arm; auto-locking magnetic handle mechanism for security when installed; and IP67 / NEMA6 waterproofing rating.

Typical applications will include tower and stack guy wires; pretensioned cable barriers; bridges; elevators; winch rope; overhead electric transit wires; fall arrest systems; aircraft cables; and utilities. It is expected to be most widely utilised in North American markets and will be officially unveiled at the National Association of Tower Erectors (NATE) annual conference, which takes place 27 February-2 March in Fort Worth, Texas. However, it will be consumed in other geographies and is available through Straightpoint’s global dealer network.

Additionally, the COLT carries many hallmarks of Straightpoint’s extensive range of equipment, including its construction from aerospace grade aluminium; exceptional battery life (up to 1,000 hours operational time); use of standard alkaline batteries; and its supply in a purpose-made carry case, suiting it to on-site cable tension measurement applications across the world.

Demonstration here

- Details

- Written by Tanya

Straightpoint’s Gavin Arnell Excels in First LEEA Examination

Straightpoint’s Gavin Arnell Excels in First LEEA ExaminationStraightpoint product technician Gavin Arnell out-performed lifting equipment professionals of far greater experience to pass the Lifting Equipment Engineers Association (LEEA) P1E Foundation Course recently.

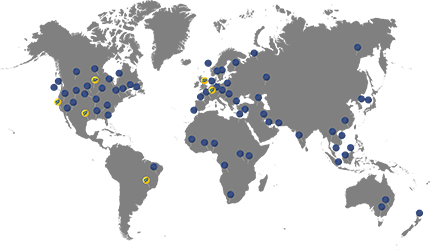

The Foundation Course is the basic level training course offered by LEEA, which is based in Huntingdon, UK but established across the globe as the leading representative body for all those involved in the lifting industry worldwide. It offers a number of courses ranging in duration and tailored for varied levels of expertise and types of equipment.

Arnell participated in a three-day programme that took place at LEEA’s Osprey Court training facility near the association’s headquarters in Ramsay Court, which is also on the Hinchingbrooke Business Park. P1E includes 28 modules covering a range of subjects including, standards and codes of practice; wire rope and wire rope slings; overhead travelling cranes; and mobile cranes.

He said: “Having never seen or heard of much of the subject matter covered by the modules, I was apprehensive about tackling the content in an exam situation. However, as the course progressed I became more confident and embraced it as a learning experience. I was still pleasantly surprised though when LEEA confirmed I had passed.”

The foundation level exam is a prerequisite for studying at advanced level and Arnell has already booked to take the Lifting Equipment General (LEG) Advanced Programme, a five-day intensive course, in April. The LEG course offers hands-on practical training to complement essential theory sessions. Content is based on lifting accessories and includes thorough examination procedures and criteria for continued periods of service.

Arnell said: “I am looking forward to the challenges of the LEG course and am sure I can apply lessons learnt in P1E to help me at the more advanced level. I know there will be lots of references to below-the-hook and rigging equipment that will reinforce my understanding about the sector of the industry in which Straightpoint operates.”

Alfie Lee, operations director at Straightpoint, said: “Gavin was the only person on the course with no previous experience and he passed first time. Some of the other candidates were on their second attempt and were perhaps not as successful even this time around. He can take a tremendous amount of encouragement and confidence from that moving forward.”

Both the P1E and LEG courses contain modules on wire rope and wire rope slings, which Lee said aligns the content with Straightpoint strategy. He explained: “We are just starting to explore the wire rope industry in greater depth. Having someone with this qualification will be invaluable and will help us understand how our customers use our products and the problems they face on a day-to-day basis within the lifting industry.”